Products

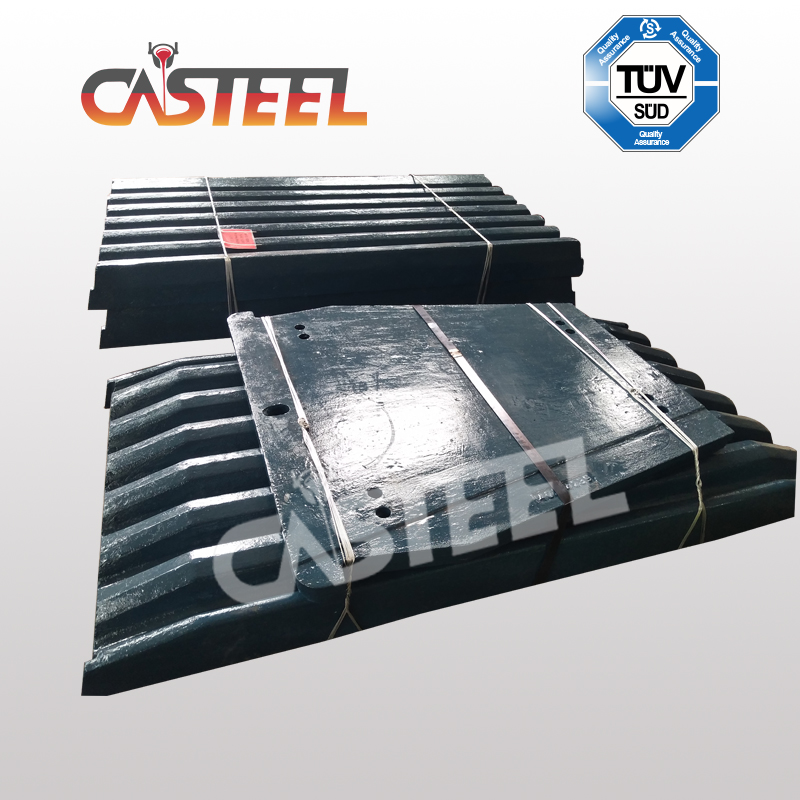

Sandvik CJ411 (JM1211) CJ412 CJ612, CJ615 Jaw Plates

Five Advantages Of Products

- Genuine Alternative

- More Wear Life

- Quality Asurance

- OEM backgroud

- Fast Delivery

Product Details

Jaw is the main component of jaw crusher, divided into movable jaw plate and fixed jaw plate two. Jaw crusher is given by the moving jaw jaw constitutes the working chamber and composition, moving jaw and fixed jaw broken under tremendous force and friction materials, easily worn, in order to protect the jaw, generally moving jaw and fixed jaw of surface mount wear liner, this liner is also known as broken boards. Surface usually made of broken plates tooth, broken tooth plate peak angle 90° ~ 120°, its size is determined by the nature of the material to be broken and the block may be, crushing bulk materials, the angle should be bigger; crushing small block of material, the angle can be smaller. Particle size of the pitch depends on the product, typically taking about equal to the width of the discharge port, tooth height and pitch ratio preferably of 0.5 ~ 0.33. Work, broken down into two parts wear plate is not the same speed, the lower wear out faster than the upper, when broken jaw crusher plates work in direct contact with the material, under enormous crushing force and friction materials, life is directly related to the broken plate efficiency and production costs jaw crusher, therefore, to extend the life of jaw crusher crushing plate is particularly important. Strengthen jaw broken crusher plate life can be considered from the design, material selection, assembly and use of the process improvements and other aspects.

Our company supply the jaw and ultra-high manganese steel manganese steel material, through scientific and strict smelting, casting, heat treatment process design and production management, high degree of wear and long life. We can produce various models, various types of jaw, welcome to leave a message or call us your detailed requirements, our first time to provide you with the perfect solution. Process advantages:

1. The material use manganese Mn18 or Mn 21 than 13% of manganese, high degree of wear and long life.

2. Work hardening technology enables jaw under pressure to continue to strengthen the hardness, high hardness.

3. The heat treatment process using the "tough water treatment" to avoid the use of naturally occurring phase transition in leaving the poor performance, good toughness.

Jinhua Steel Casting And Engineering Parts Co., Ltd.

Contact Person: Mr. Johnson Wang

Department: Export Dept.

Post: Director

Telephone: +8615958452539

Landline: +86 579 82708200

Company Address: Room 1602, Building 10, Wanda Palza ,169 Guang Nan Road, Jindong District, Jinhua, Zhejiang ,China.

Factory Address: Room 2022-2023, Building 2 East Side of Jifan Street, Wucheng District, Jinhua, Zhejiang, China

Website: steelcasting.us764.com

Previous: Telsmith H2238,H2550,H3244,H3450,...

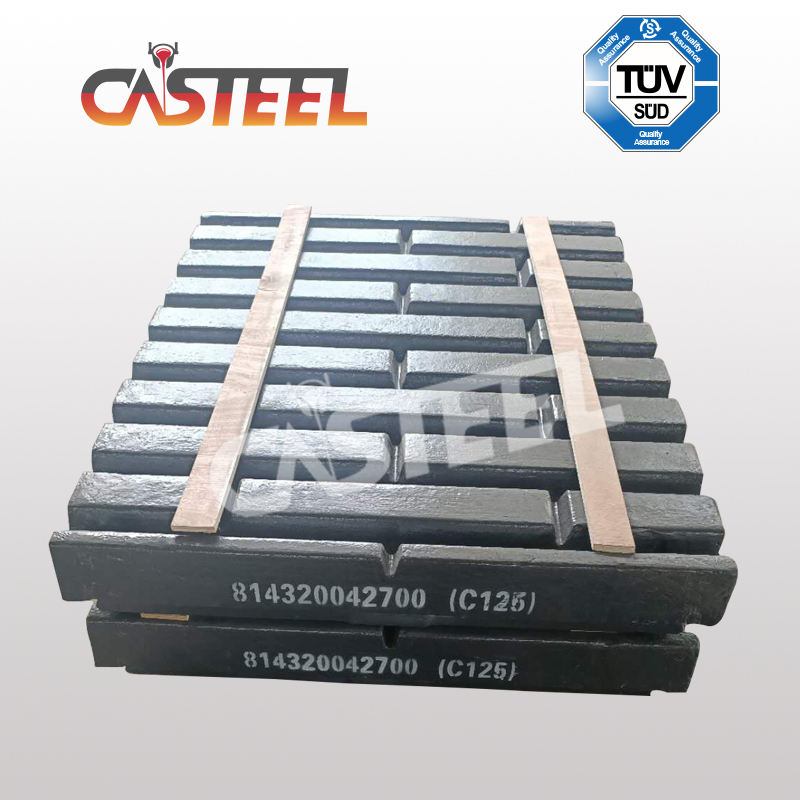

Lokomo C125b Jaw Crusher Parts, Plate Jaw Fixed, Jaw Movable

High Manganese C125 Chrome Material Wearing Spare Parts F...

PE-1000x1200 Jaw Crusher Parts, Fixed /Swing Jaw Pla...

Genuine Spare Parts for Sandvik Cj211, Cj411 Jaw Plate OE...

Kleemann Mc120 PRO Jaw Crusher Plate, Side Plate, Cheek P...

MC110 Jaw Plate Fixed and Swing for Kleemann Mobile Crusher

Cedarapids Cj3042 Jaw Plate, Jaw Die, Jaw Fixed